Cómo implementar sistemas de purificación con cerámica: Guía técnica para emisiones ultra bajas en hornos industriales

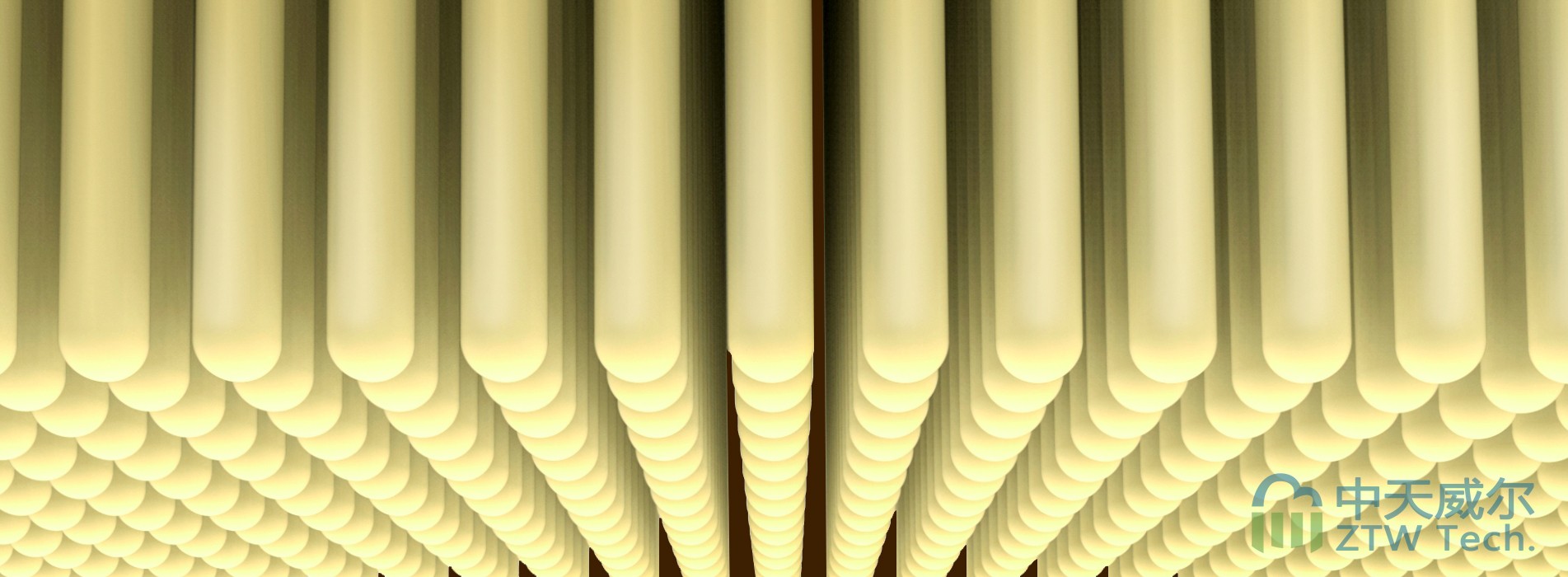

Cómo implementar sistemas de purificación con cerámica: Guía técnica para emisiones ultra bajas en hornos industriales 1. Fundamentos técnicos de la purificación cerámica: Más allá de la filtración convencional La implementación de sistemas de purificación con cerámica ha revolucionado el control de emisiones industriales, especialmente en aplicaciones donde los métodos tradicionales encuentran limitaciones técnicas insuperables. […]